As marble is a natural stone ,so there is always some color and vein variation from blocks to blocks, yet , as a professional marble manufacturer , we can always try ways to make color in agreed color range ,with each sheets evenly displayed and no obvious color difference from sheets to sheets. So that when sheets are interlocked together ,all sheets are just like one .

Below are our procedures to ensure you from such worry :

1, RAW MATERIAL SELECTION

---With the approved sample at hands , we find out the raw material with closest color background and veins, which is the first but most important step , to find the right material !

2, COLOR SORTING BEFORE AND AFTER CUTTING

--- Workers will sort out those BROKEN TILES with obvious color difference, to limit wrong material from mixing into mass production avoiding wasting time to cut wrong material to throw away. And make a rough sorting when chips are out.

3, COLOR SORTING BEFORE MESH MOUNTING

---Workers will finer sorting before they put chips into the mould and do mesh mounting .

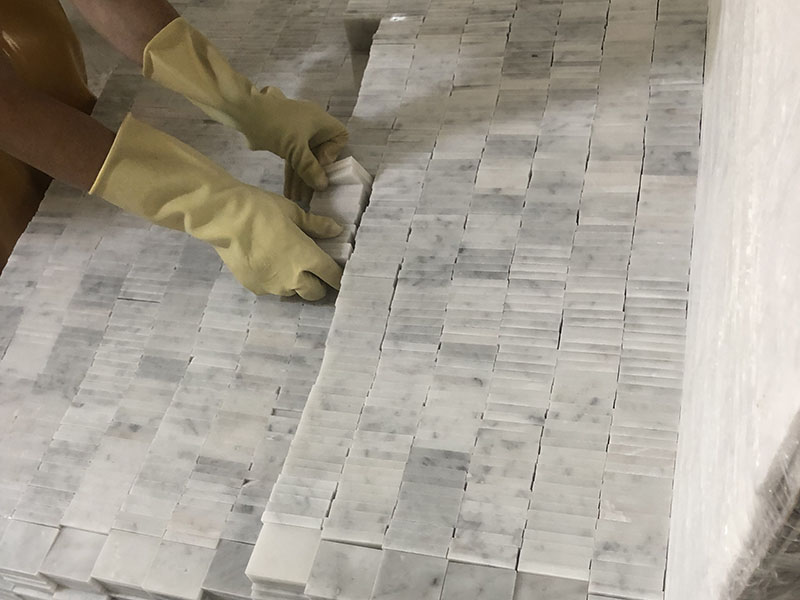

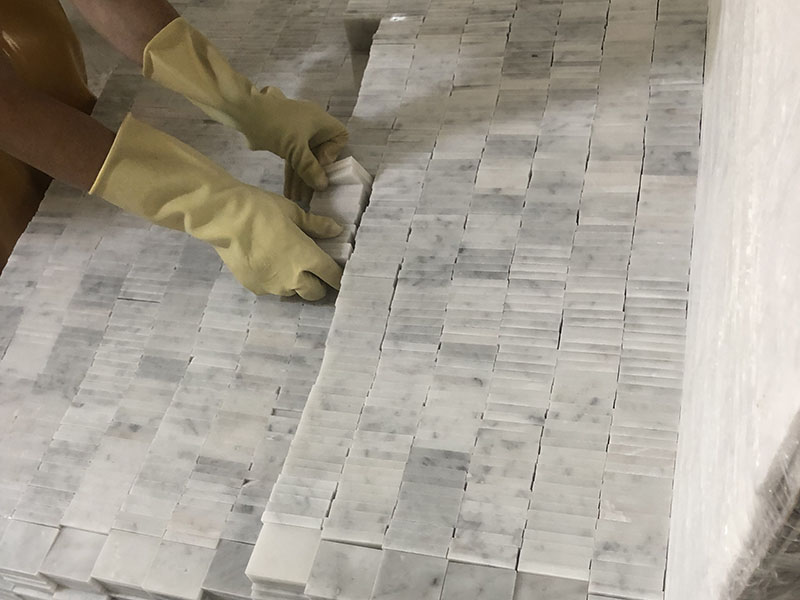

4, FINAL INSPECTION

---As chips are still wet when they are mesh-mounted , so there can be still some color/quality issue after products are finished and dried . Our On line inspection solves this problem. When we do final inspection ,we take sheets from different stacks of production and interlock them together to check if colors are in consistence with each other .